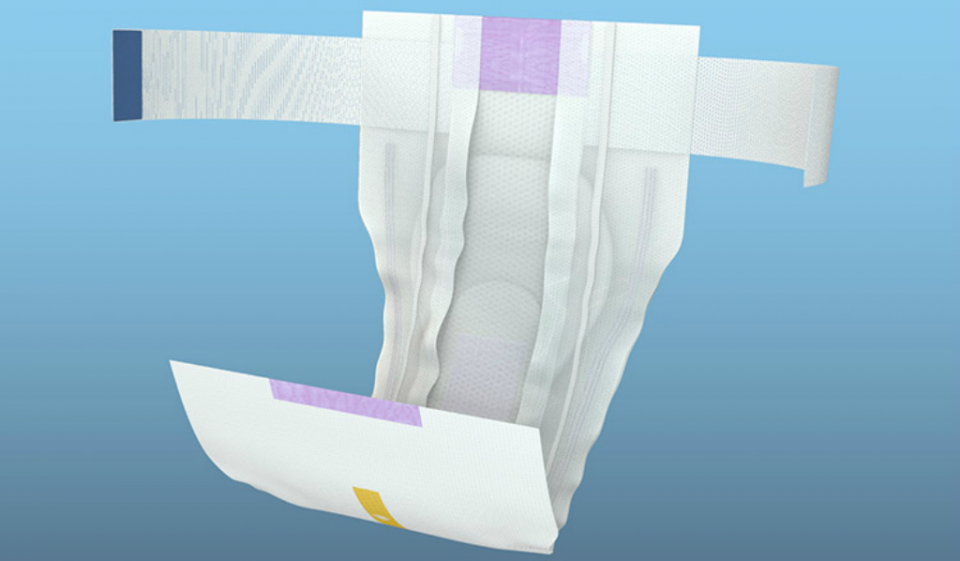

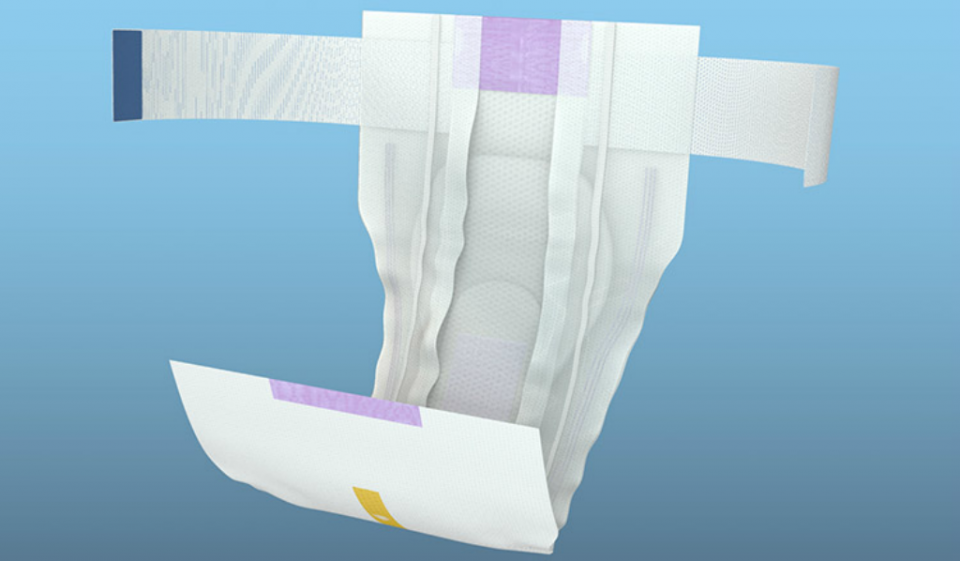

Belt

Adult brief Belt enhances comfort and wearability thanks to the Belt feature ensuring product fit and body-hugging flexibility.

Dealing with Moderate and High incontinence,

consumers look for the highest product performance

without compromising on fit and comfort:

explore different product designs to satisfy these needs.

Adult brief Belt enhances comfort and wearability thanks to the Belt feature ensuring product fit and body-hugging flexibility.

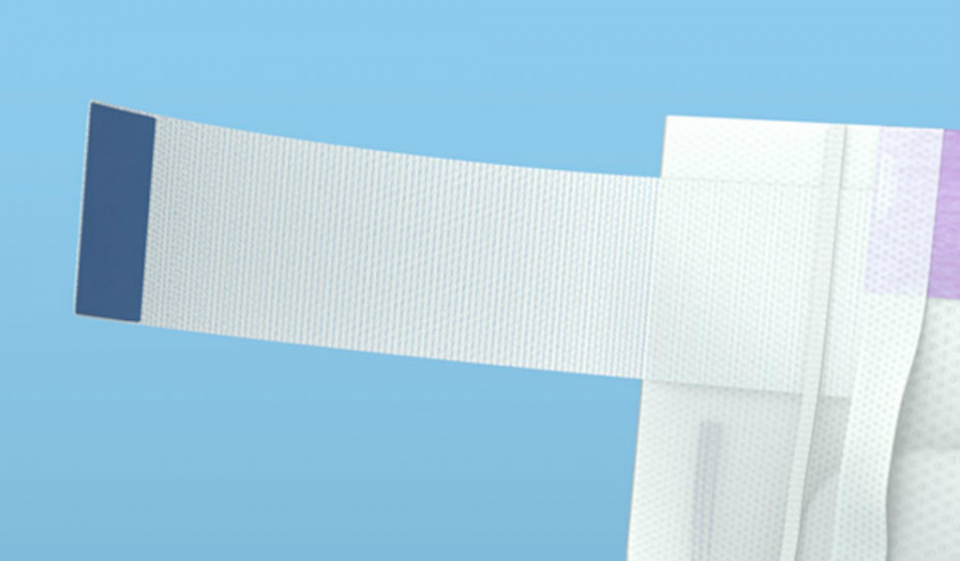

TECHNOLOGY

Waist band pre-made applied between topsheet & backsheet

RAW MATERIALS

Fluted/NW elastic 22-25 N/mm

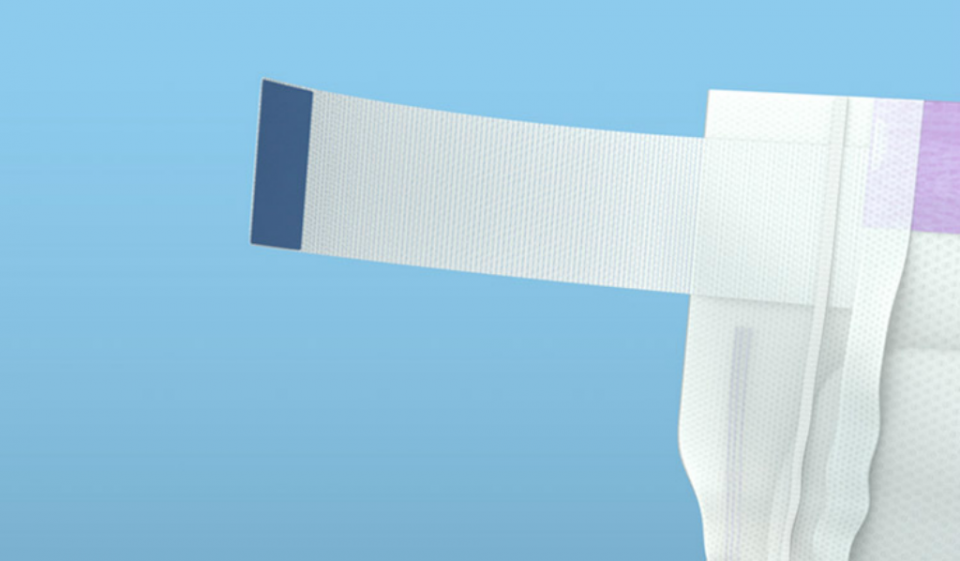

TECHNOLOGY

Rear belt panel with tape tab closure

Rear rectangular elastic panel in 2 pieces (rigid/elastic)

RAW MATERIALS

NW elastic tri-laminated 93-165 g/m2

NW hydrophobic, spunbond hydrophobic 30-50 g/m2

TECHNOLOGY

Continuous hook lamination on rear panel

Discrete double hook tape tab closure on rear panel

Discrete double hook tape tab closure on topsheet

RAW MATERIALS

PP-soft NW, PP-film, TPE extruded film (three layers), Y-bond

PP-NW, PP-film (two layers), Y-bond

PP-NW, PP-film (two layers)

PP-PP adhesive film, Y-bond

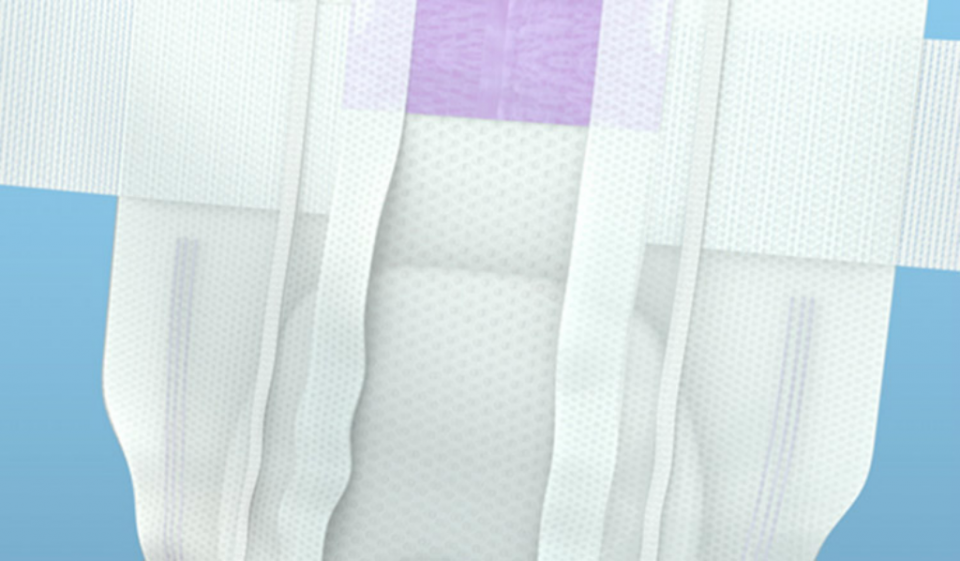

TECHNOLOGY

Central topsheet construction

RAW MATERIALS

NW spunbond-hydrophilic 13-20 g/m2

TECHNOLOGY

Lotion applicator

RAW MATERIALS

Aloe vera 20 g/m2

TECHNOLOGY

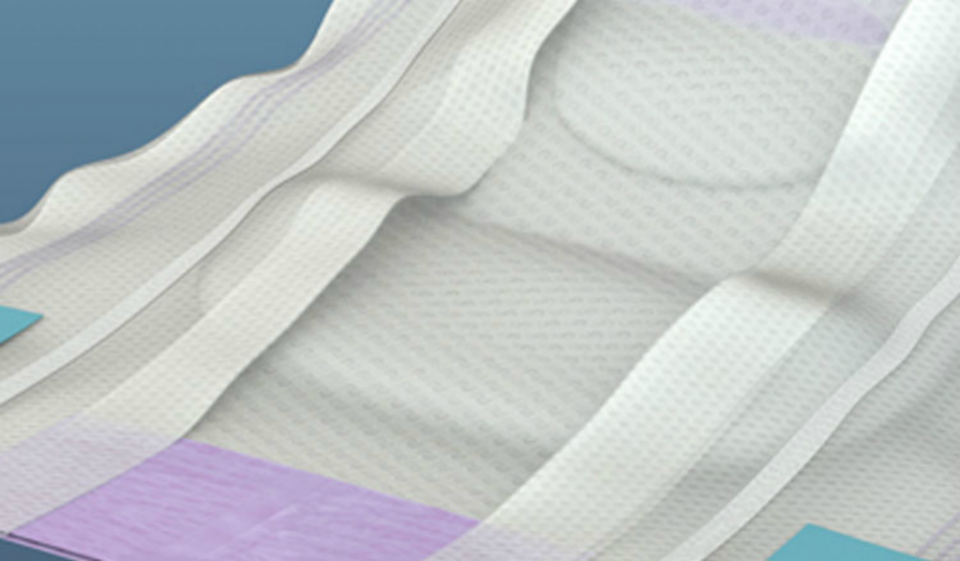

2D double core

Target SAP

2D smaller core wrapped+2D bigger core in top position+direct mills

RAW MATERIALS

Cellulose untreated 700-800 g/m2

SAP

NW SMS/SB 8-13 g/m2

Tissue/paper 17-20 g/m2

NW spunbond 8-12 g/m2

TECHNOLOGY

Shaped contour cut (anatomic chassis type)

TECHNOLOGY

Acquisition layer glue bonding on topsheet

Acquisition layer spool

Acquisition layer ultrasonic bonded on topsheet

Acquisition layer with E-cam technology

RAW MATERIALS

Airthrough bonded-hydrophilic 30-80 g/m2

Microperforated poly 20-50 g/m2

TECHNOLOGY

Cuffs attachment by glue

Cuffs attachment by USB

Cuffs elastic entrapment by USB

RAW MATERIALS

NW SMS-hydrophobic 12-15 g/m2

Yarn elastic 800-940 dtex

TECHNOLOGY

Curved leg elastics applicator with control yarn tensioning system

RAW MATERIALS

Yarn elastic 800-940 dtex

TECHNOLOGY

Textile backsheet laminated (in line glued)

RAW MATERIALS

NW/film pre-combined unbreathable white 25-34 g/m2

NW/film pre combined breathable white 22-34 g/m2

NW/film pre-combined four colors registered 22-38 g/m2

NW SS-hydrophobic 13-20 g/m2

PE film 15-30 g/m2

NW spunbond 10-14 g/m2

TECHNOLOGY

Wetness inkjet print

Wetness strip/s application

RAW MATERIALS

Hot melt adhesive with color change to exposure of liquid 50 g/m2