GDM Core Plus

The Disposable Hygiene Market is becoming more complex and competitive. In such a scenario, responding promptly to diversified market demands is pivotal for businesses to thrive.

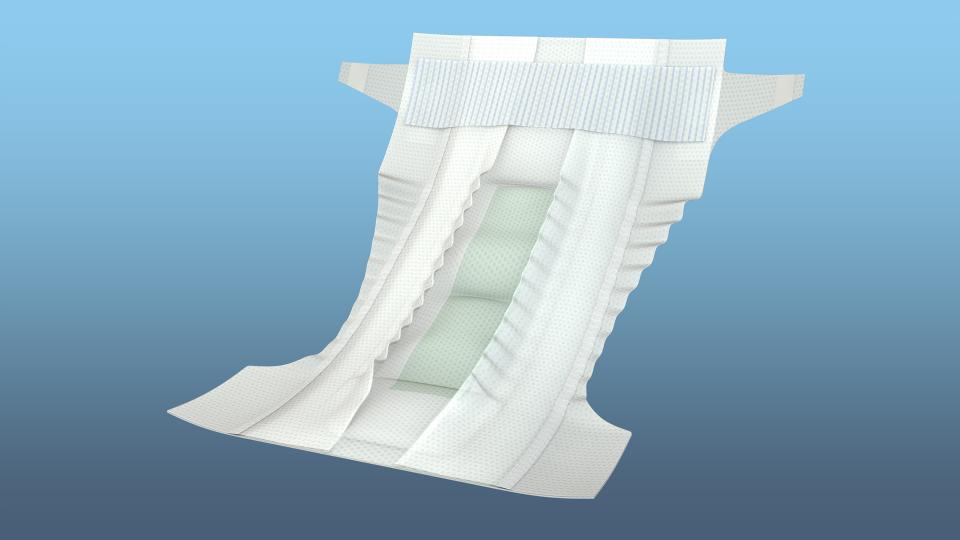

End users want products to be performant, affordable, soft, and pliable. Manufacturers, on the other hand, need their product to be stable, flexible, and homogeneous. Creating customized cores for different products and needs allows to satisfy both manufacturers and purchasers.

And this is exactly what GDM Core Plus is about: a sophisticated yet easy to operate technology that can respond to different needs, while it guarantees innumerable benefits.

Successfully developed and launched to the market in 2012, GDM Core Plus leverages advanced CFD (Computational Fluid Dynamic) simulations, allowing the customer to anticipate the final output through mathematic models of the raw materials, and thus ensuring wearability, flexibility, performance, and cost effectiveness.

GDM Core Plus has already been installed on several production lines, proving to be as efficient as it is profitable.

Should you like to dive deeper into this technology, do not hesitate to get in touch.