The disruptive innovation at the core of disposable baby diapers

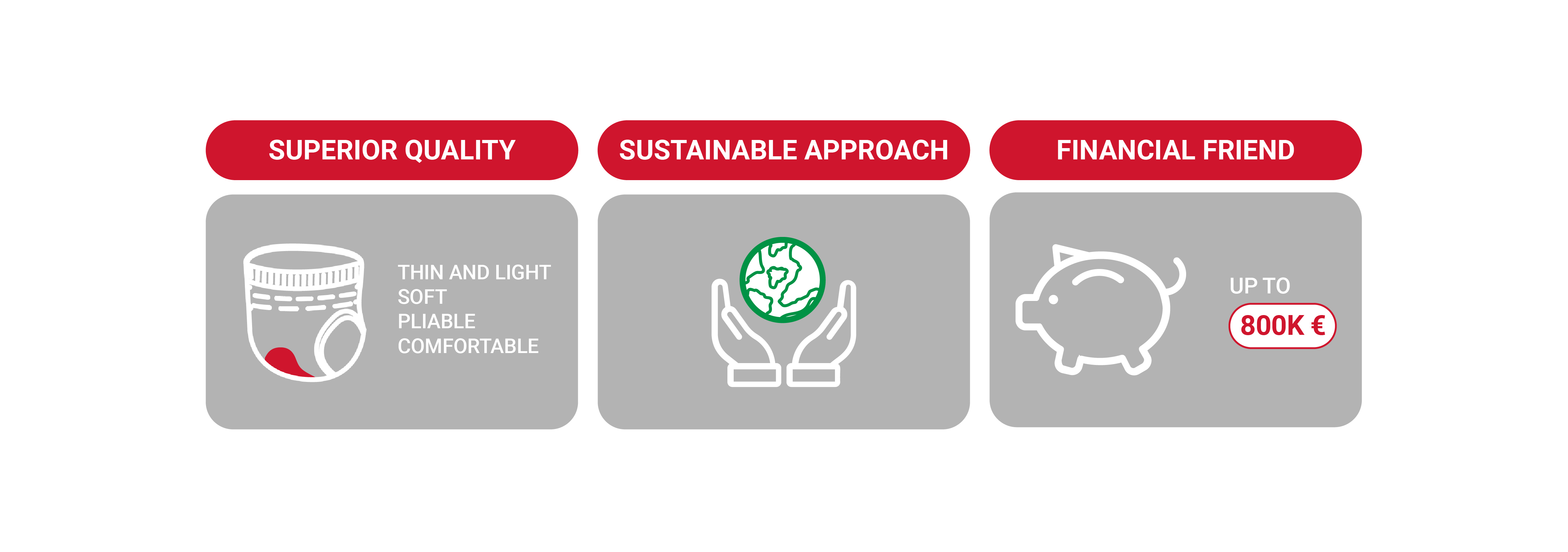

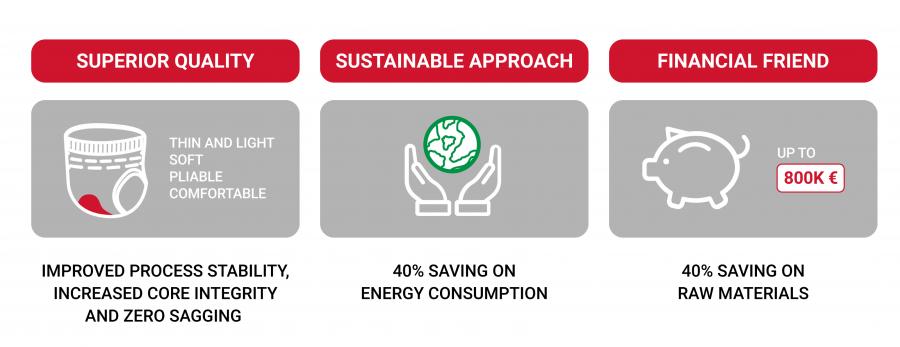

The aim of this white paper is to define the evolution of GDM’s diaper core in recent years. Starting from the consumer needs in the developed market, we have built an innovative technology called the Extra Thin Core that provides superior absorbency and dryness while also minimizing swelling and sagging. Not only that: Extra Thin Core grants many advantages to the manufacturer in terms of lower power consumption and material savings up to €800,000 per year.

What the diaper core is and why it is so important

The term disposable hygiene refers to single-use hygiene products like baby diapers, sanitary napkins, pantyliners, tampons, adult briefs and protective underwear. Among these categories one of the most prominent is the baby one, whose products, the diapers, were invented in the 1900s.

The diaper, primarily composed of polypropylene, cellulose and a superabsorbent polymer, is made of four components:

- the backsheet, not in contact with the skin, is the external layer whose main duty is to ensure water resistance and creates a proper fit around the legs;

- the topsheet, which comes into contact with the baby’s skin, has been designed to quickly transfer fluids to the core while remaining soft and dry to the touch;

- the acquisition and distribution layer, which is right below the topsheet, with the function to accelerate the penetration and diffusion of liquid;

- the absorbent core, the latter being the innermost layer of the diaper, typically consisting of a blend of cellulose fluff pulp and SAP (polyacrylate granules)[1].

The challenge of a superior-quality disposable baby diaper core

The first significant core performance improvement occurred in the 1980s with the introduction of superabsorbent polymers - special materials able to absorb several times their weight in fluids. Since then, what could be the innovation core-wise?

In mature markets such as Europe, North America and Japan, where volumes are stagnating or decreasing, shoppers consider many different aspects when buying baby diapers, but there is one main feature that comes above all: quality.

This is why brands have started to innovate their product lines strongly investing in improving Baby Diapers and Pants’ performance and comfort, with the aim to meet consumers' needs while remaining competitive.

In a market as saturated as that of developed countries, growth prospects are negative and costs are high. With the emergence of new segments such as affordable premium and super premium, manufacturers are on the lookout for cost-efficient opportunities that fill the demand for a high-performance, lighter, thin core. Here comes the GDM Extra Thin Core.

Extra Thin Core: the heart of the baby diaper

In recent years, the latest product development trends have been focusing on high-quality improvements prioritizing absorbency/leakage protection as well as thinner and lighter products.

One of the main challenges for manufacturers is to work on the core that must comply with the drivers stated above.

But how can we increase product performance, improve fit and wearability while keeping the budget under control?

GDM’s answer is Extra Thin Core. Let’s discover the main advantages.

Extra Thin Core product advantages: increased product performance, improved fit and wearability

GDM's Extra Thin Core technology stands out from the competition due to many remarkable advantages:

-

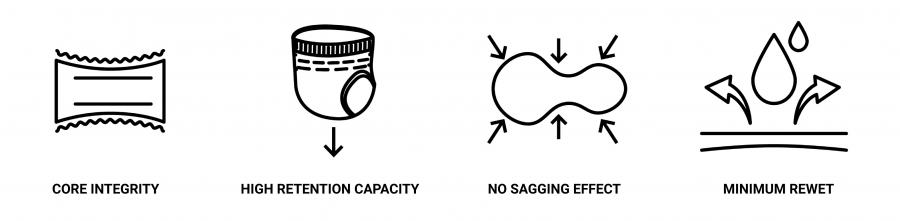

Improve process stability: Extra Thin Core reduces the core weight variation vs the target weight, with a variability lower than 1.5%. The process ensures the same performance for all the same products.

-

Increase core integrity: the technology grants an outstanding liquid spread and core stability, delivering higher-than-average quality in terms of leakage and skin protection. This is due to a unique mix and distribution of fluff and SAP.

In addition, when the diaper is enabled with Extra Thin Core with the optional permanent channels’ feature, it shows a

homogeneous weight distribution in the channel cross section. -

Zero sagging: by reducing the fluff amount and introducing the channels’ feature, thanks to the Extra Thin Core technology, the diaper doesn’t get flabby and drooping over time, remaining compact thus cozy and skin-friendly.

High absorption, low acquisition time and rewet and skin-friendliness are confirmed by benchmark lab tests, conducted by an independent laboratory, on GDM's baby diapers manufactured with Extra Thin Core vs the European market reference.

Rewet test outstanding results, assessing diaper surface dryness

+40% on daily use*

+30% on night use*

The low liquid Acquisition time, keeping the liquid away from the skin, guarantees high skin protection

*vs best-selling open diaper with permanent channels

Extra Thin Core budget advantages: creating value across the value chain

Not only does Extra Thin Core meet the consumer market demand for leakage-resistant, comfortable, skin-friendly diapers, it also ensures an improvement for the manufacturer in terms of savings.

The technology allows to save up to 800 k€ per year (internal estimation on Fluff and SAP consumption for 260 mn pcs/year, compared to previous core formation process; fluff price = 900€/tons): a 40% saving on core materials thanks to an optimized mix and allocation featuring permanent channels construction (option) and process stability.

The Extra Thin Core is more space-saving than competing solutions. Thanks to its distinctive design the core takes up to 25% less space on the shelf as well as in the stockroom and in containers. Because of this, it allows for more diapers to be stacked and transported at the same time with lower costs.

Moreover, the process has been designed to minimize the use of air for fluff and SAP transport. The resizing of the suction fan of the forming wheel and the mill redesign have further contributed to the reduction of energy consumption up to 40% compared to the traditional version.

Extra Thin Core: what the future holds

One of the most important factors to consider in order to assess the future of this technology is that Extra Thin Core benefits from an extremely positive set of market conditions:

Developing countries are increasingly important in the disposable hygiene market and manufacturers demand effective solutions. Rising living standards, higher disposable income, greater health and hygiene awareness: all these factors bode very well for Extra Thin Core. With more and more consumers looking for affordable solutions, a technology like that of Extra Thin Core combining state-of-the-art leakage protection and premium comfort could become more interesting in the coming years.

Although Extra Thin Core was originally developed to address the needs of the Baby market, it has already found applications in the Adult Inco category over years. Indeed, both Adult Briefs and Protective Underwear segments are growing at an accelerated pace with products ensuring discretion, privacy and coziness. This is mainly due to the emergence of the Silver Society, a manifestation of a long-term demographic trend where the elders are living a second youth, enjoying highly satisfying, socially active, fast-paced lives. For this age group, performance and discretion are by far the most requested features in a disposable hygiene product. Given this phenomenon and the high rate of growth currently undergoing in the Adult Inco market, it is only reasonable to assume that Extra Thin Core will keep growing in this market as well.

The Extra Thin core technology has long been a core part of GDM’s Baby and Adult Inco portfolio and it is currently installed in several machines around the globe.

The technology is available on GDM lines but also as a kit, therefore it can be integrated with new and old machines alike.

More and more consumers are demanding absorbency, comfort, dryness and discretion. Can you deliver? If you’re a manufacturer looking for cost-efficient opportunities that fill the demand: contact us.