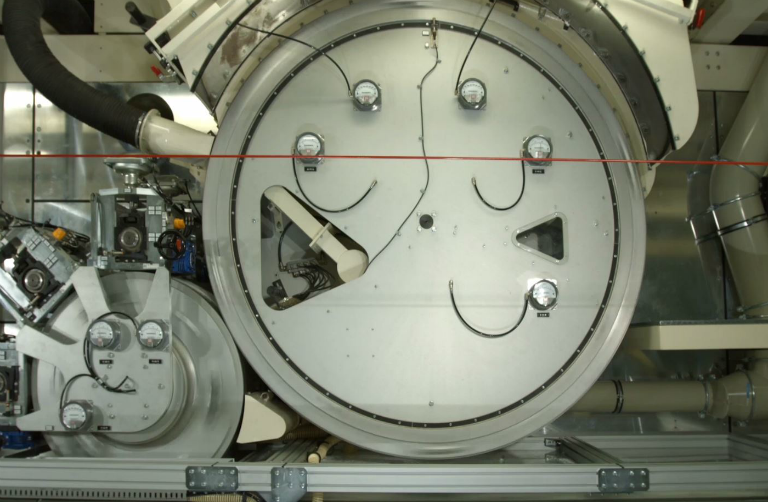

Focus on Flexibility

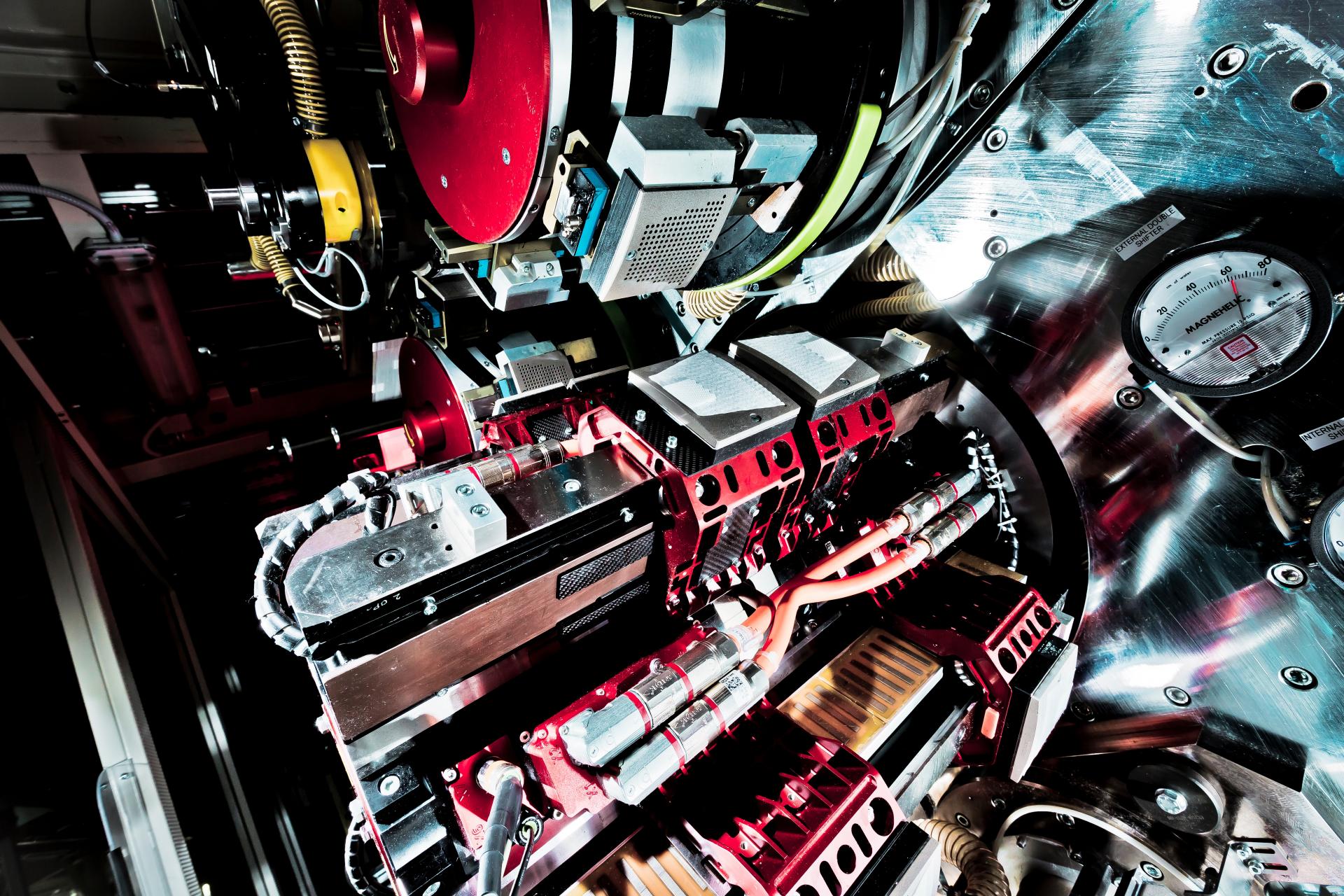

Customers needing frequent material and size changes in their production process will find the solutions focused on flexibility extremely interesting. These lines are designed to minimize the impact of size change activities and to easily set-up raw materials.