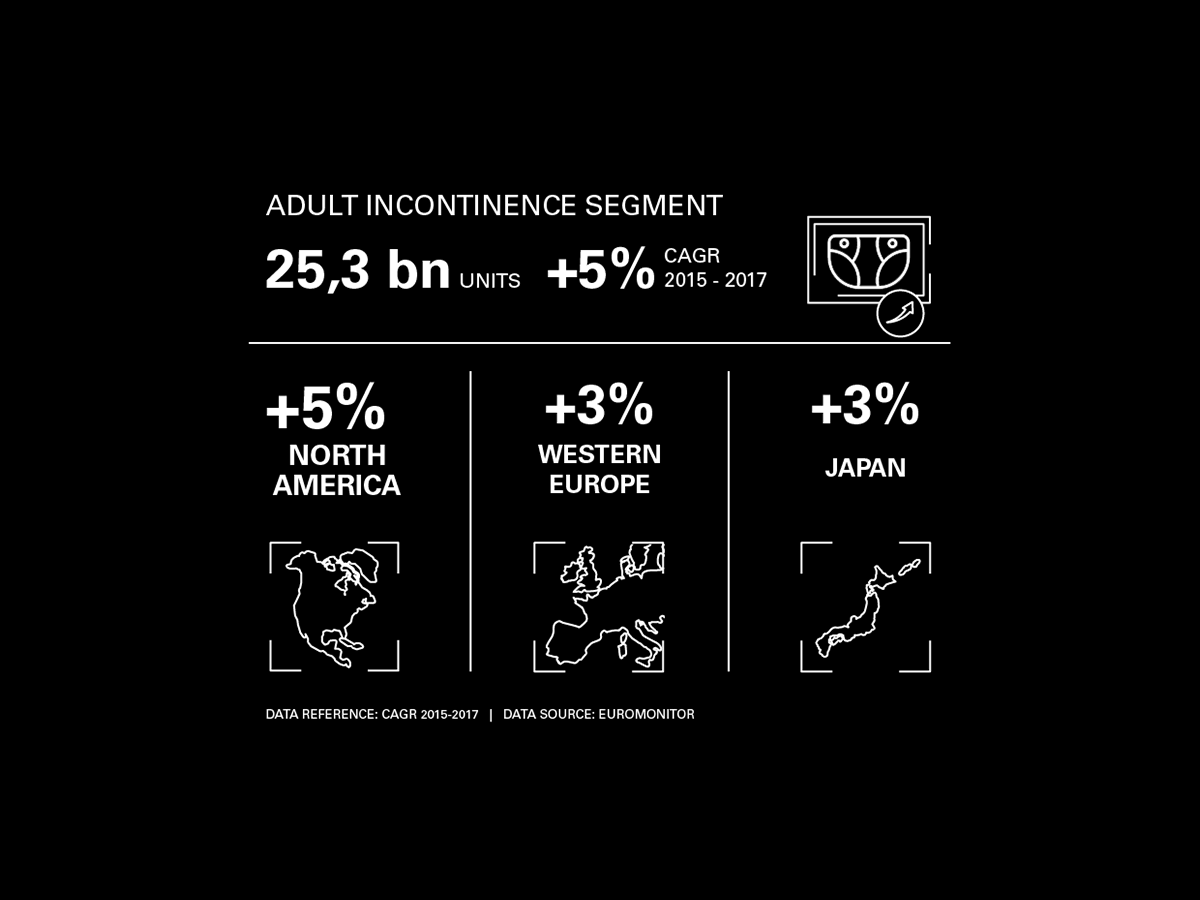

How are manufacturers approaching the market?

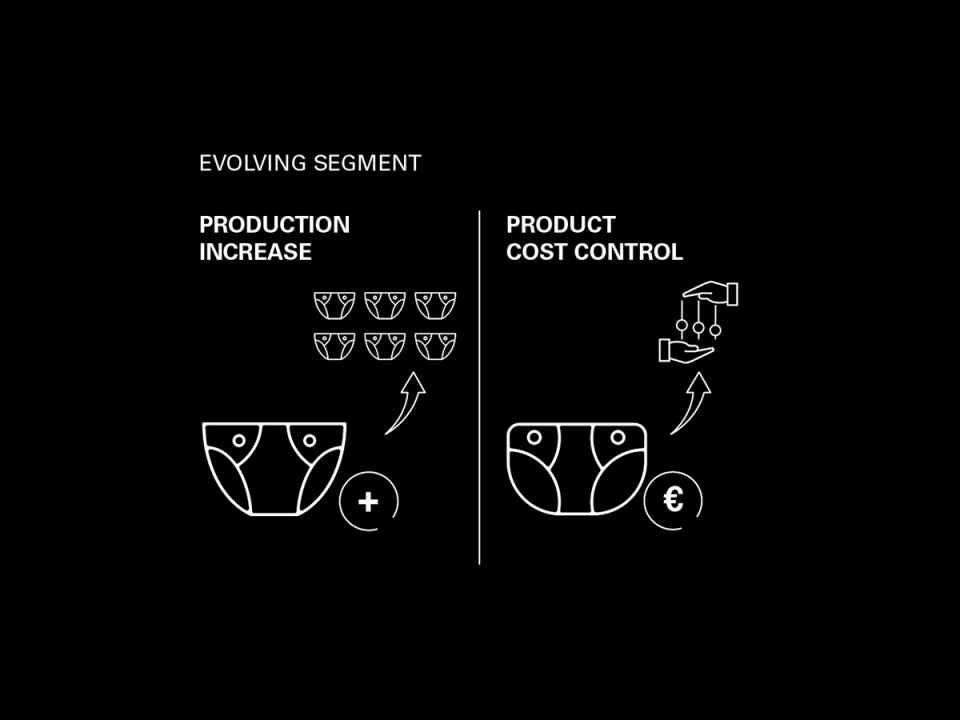

Considering the strong impact of fast changing people lifestyles, the adult incontinence segment is characterized by:

- Evolving consumers' needs in terms of features and availability: new products with better management of breathability

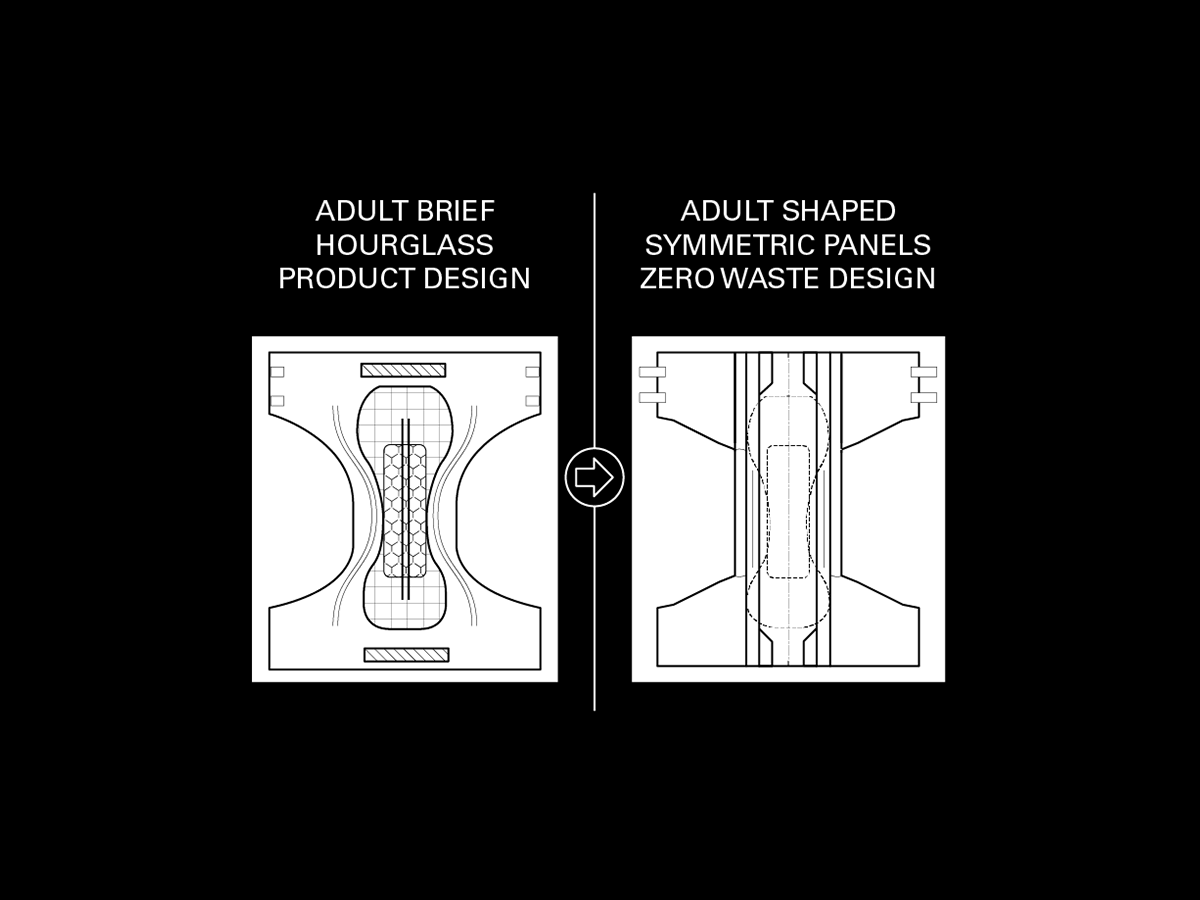

- Increasing offer of traditional and shaped products, to deliver unique new solutions and satisfy consumers' different needs

- Manufacturers have to constantly monitor operative costs without compromising on quality and product feature requirements