Zero Time

Zero time is the evolution of the time saving concept: using advanced process and technical solutions, the size change over operations time is consistently reduced.

Zero time is the evolution of the time saving concept: using advanced process and technical solutions, the size change over operations time is consistently reduced.

New process based on the “Zero Waste” concept for the application of the rear zero waste wings in baby diaper products established on the Linear Motion.

A process sequence of rear shaped wings application (without scraps) independent from the material characteristics and able to achieve high speed performances (baby diaper lines at 1200ppm).

This kit allows the reduction of changeover time for this applicator.

Thanks to the E-cam technology, GDM has developed a new process based on the application of the front zero waste wings in baby diaper products: this solution, applied on the final accelerator, allows to simplify the changeover operations and also turns the machine setting time down to zero .

This upgrade kit is furnished for high speed performances (baby diaper lines at 1200ppm) with symmetrically shaped wings.

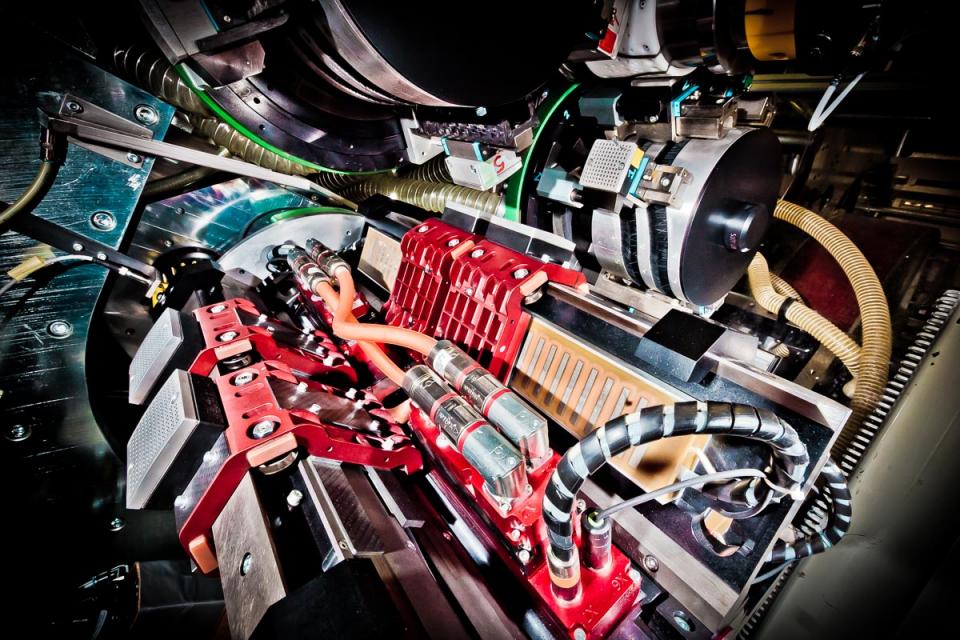

Exploiting new Technologies applied to servomotors and drives, GDM has developed a system to control the Tape Tab application onto the Adult machines rear panels, in order to minimize changeover, maintenance and setup operation by using a single typology of applicator to produce multiple sizes.

Thanks to a specific speed profile (designed by GDM), which is used to synchronize the applicator servomotors speeds during application process, and a sliding system that allows a fast cross machine unit relocation, the same applicator is suitable to produce from small to x-large size range.

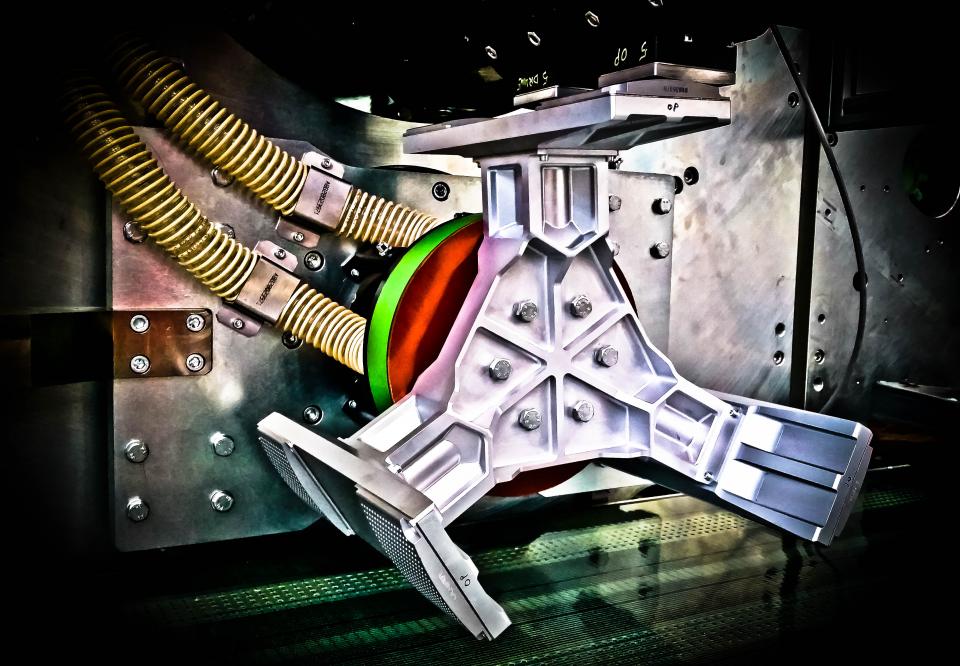

The kit consists of a process sequence for the application of the front and rear zero waste panels in Adult diaper products based on the Linear Motion technology which allows the crosswise reposition of the panels application.

The new shaped panel Zero Waste design will allow you to reduce up to 30% of the total consumption of non woven materials in the product, ensuring a better quality product thanks to the GDM unique process sequence for panel application and folding. Quick change over operations are made possible by electronic setting and updating through HMI.

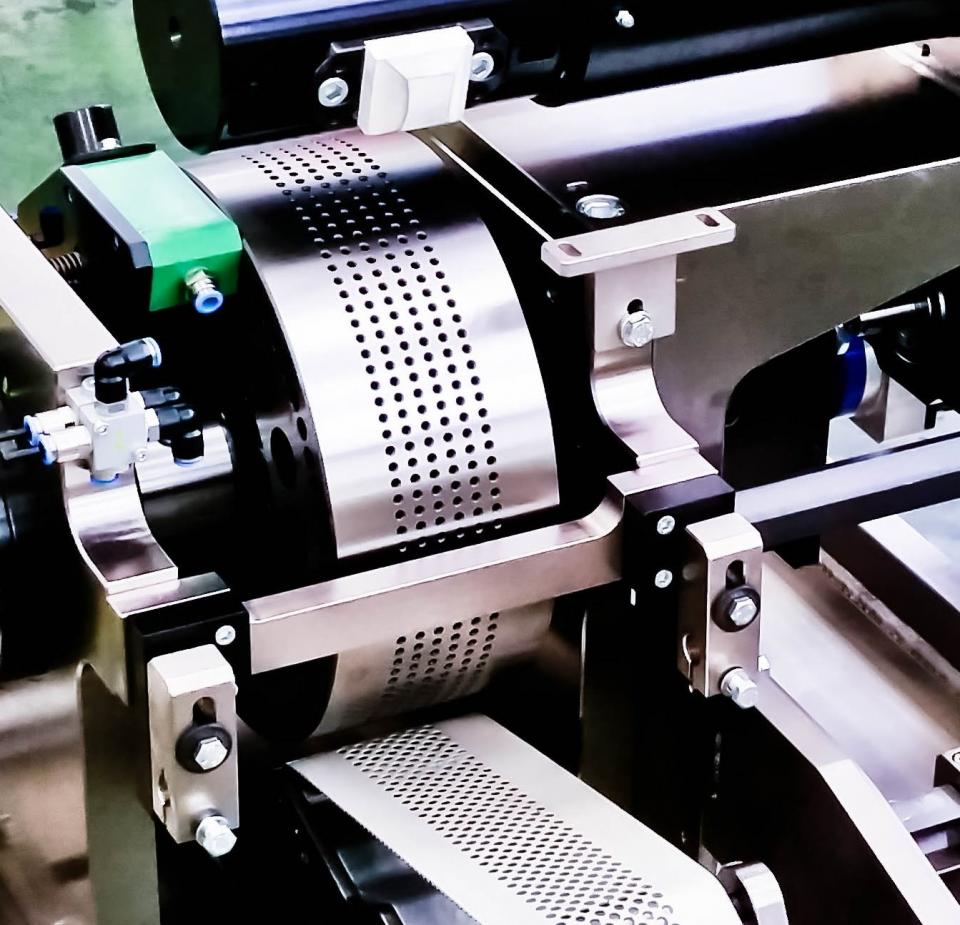

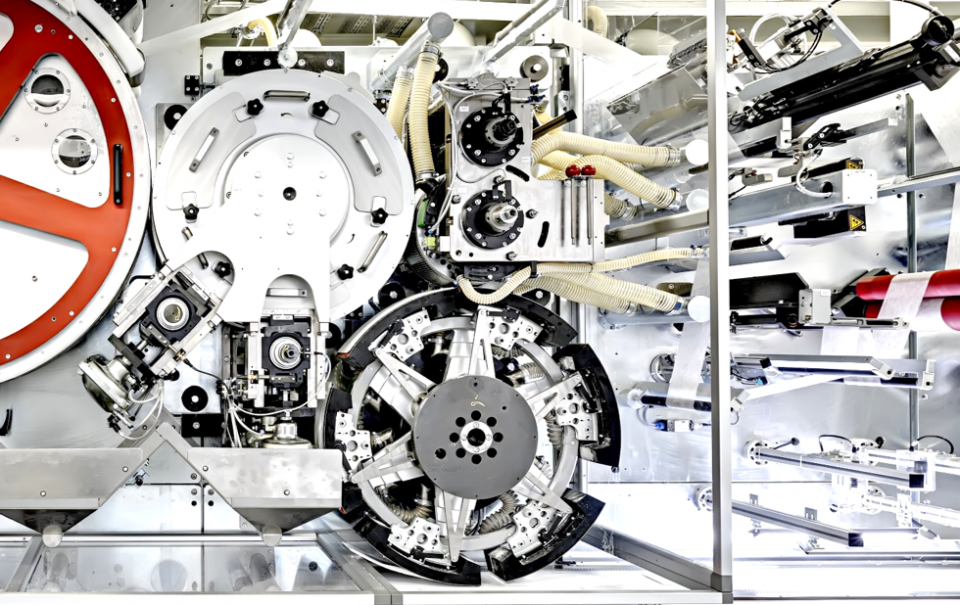

Exploiting new technologies applied to servomotors and drives, GDM has developed a system to control the Core Cutter process in order to minimize changeover, maintenance and setup operations by using a single unit producing multiple sizes.

The unit is equipped with two servomotors in order to drive the cutting roller and the under vacuum anvil roller independently. A specific GDM designed speed profile is used to synchronize the speed of the cutting roller with the vacuum anvil roller during cutting, adapting it according to different size lengths.

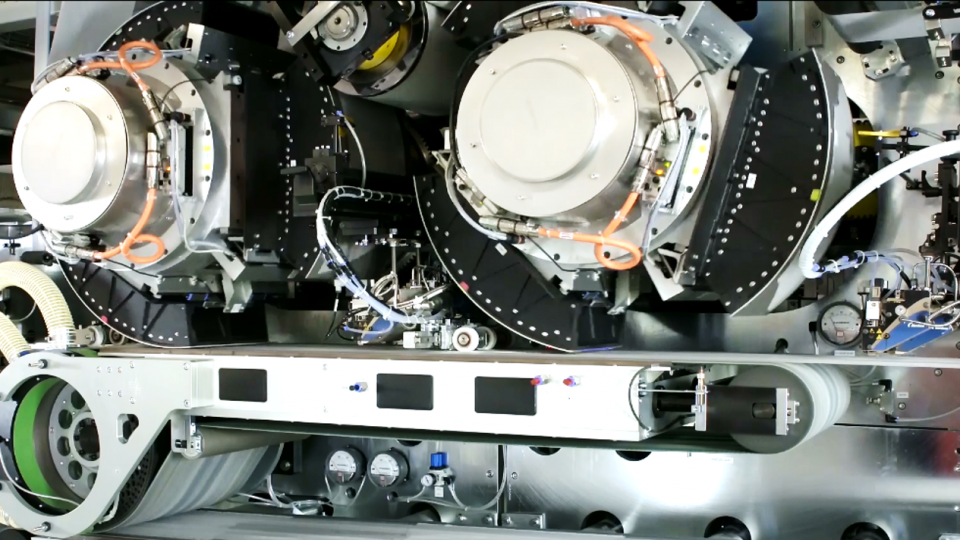

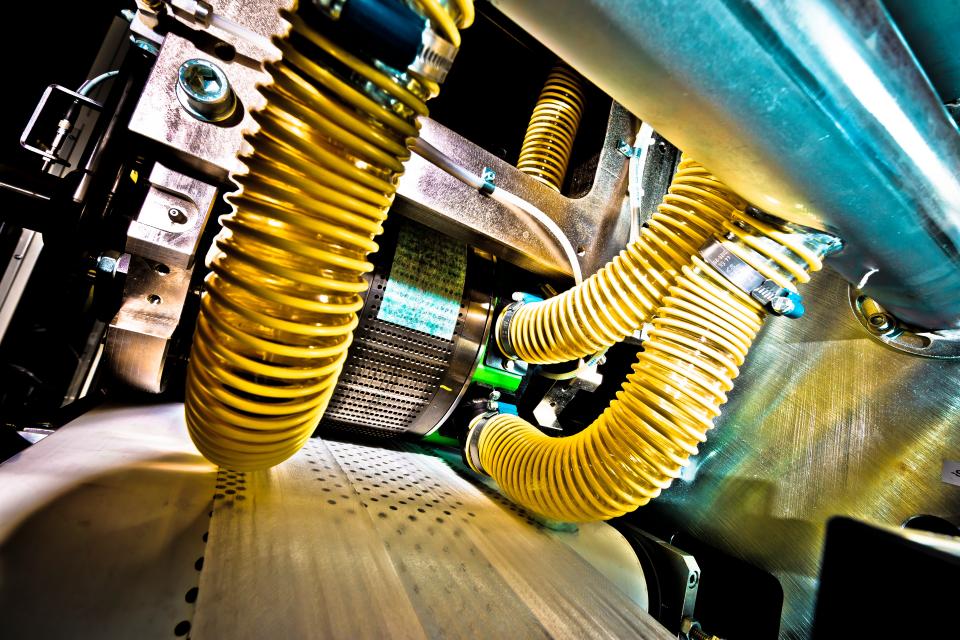

Exploiting new technologies applied on servomotors and drives, GDM has developed a system to control the Acquisition Layer application process in order to minimize changeover, maintenance and setup operations by using a single unit producing multiple sizes.

The unit is equipped with two servomotors in order to drive the cutting roller and the under vacuum anvil roller independently.

A specific GDM designed speed profile is used to synchronize the speed of the cutting roller with the vacuum anvil roller during cutting, adapting it according to different size lengths.