Zero Defects

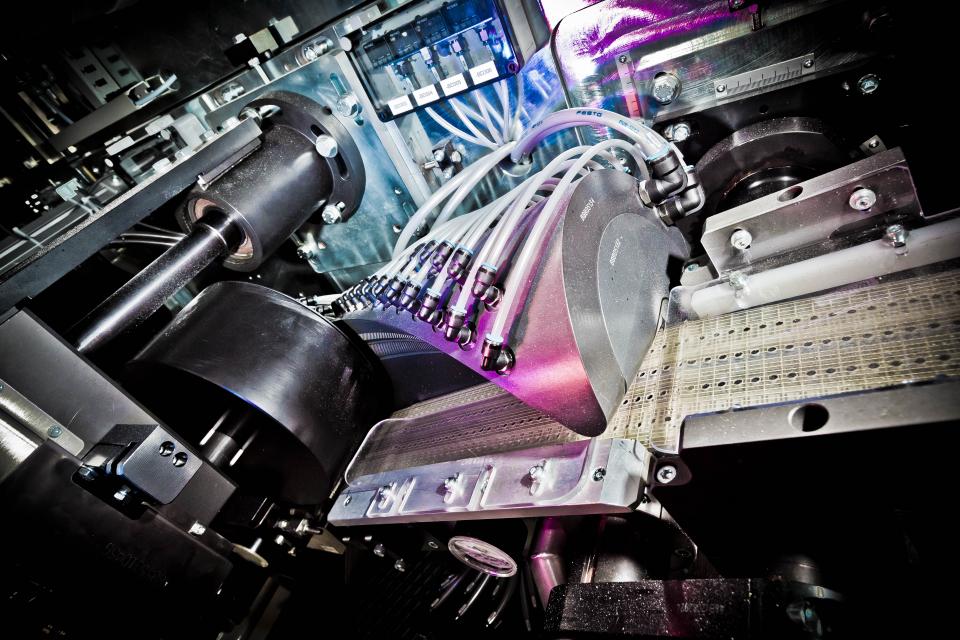

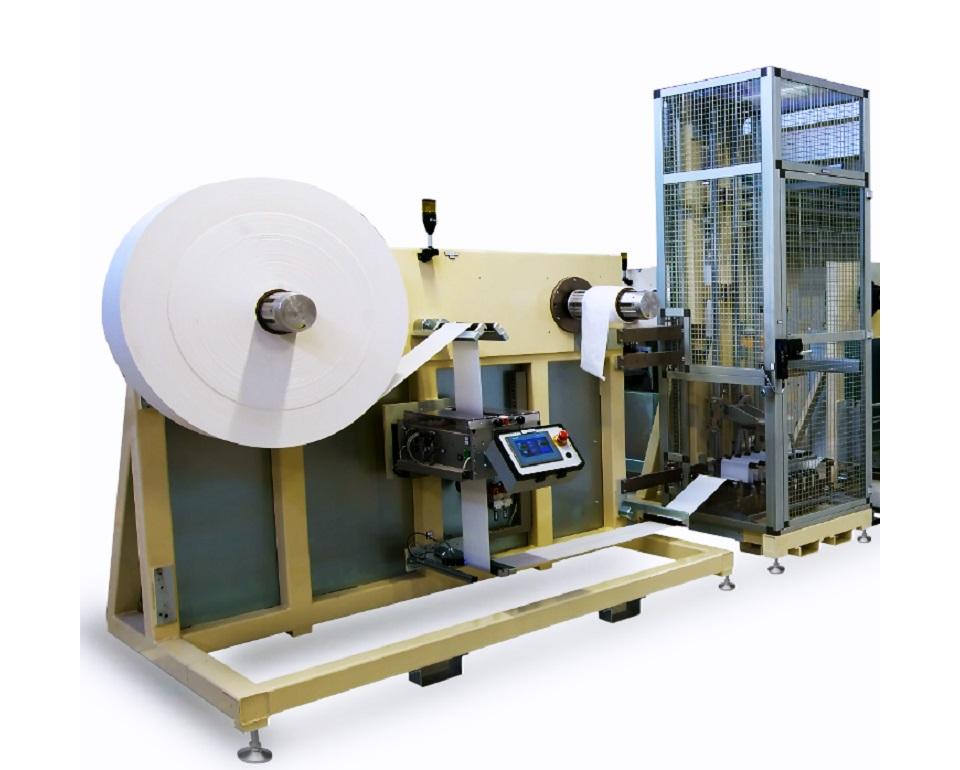

The objective of these kits is to satisfy the market demand concerning the quality of the final product. Zero Defects is a way of thinking and doing that reinforces the notion that defects are not acceptable. With a philosophy of zero defects, our customers can reduce the cost of failure and increase revenues through increased customer satisfaction.