Zero Glue

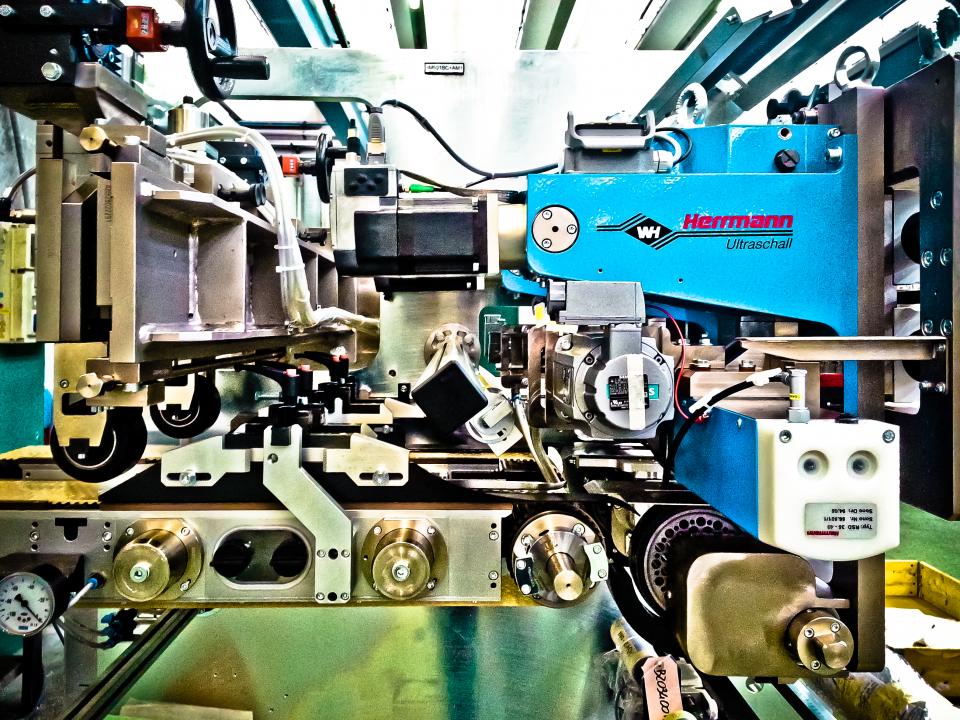

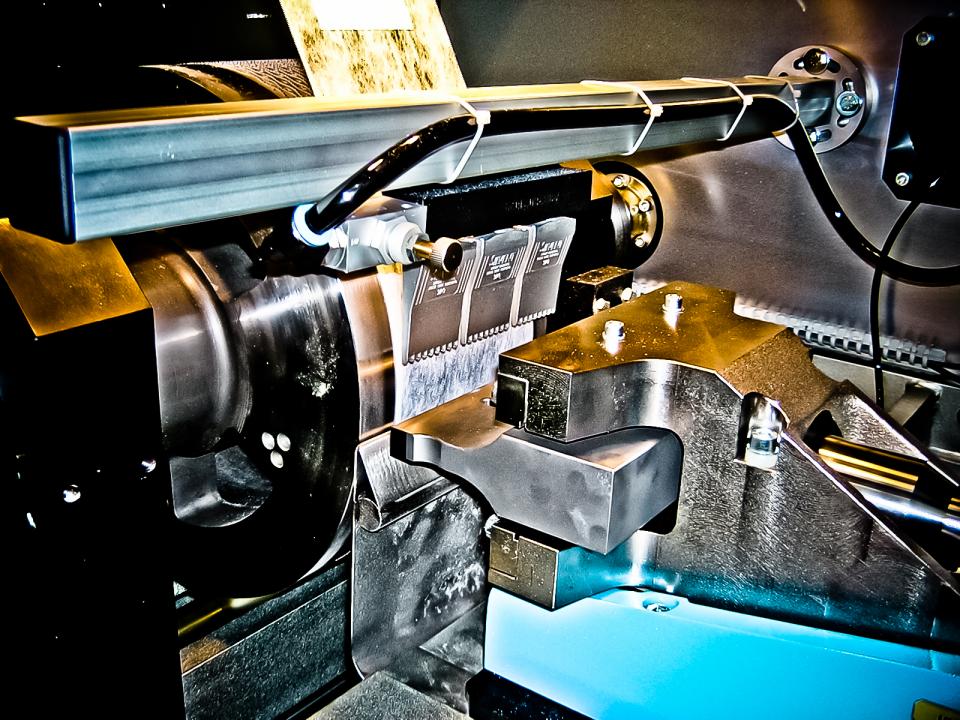

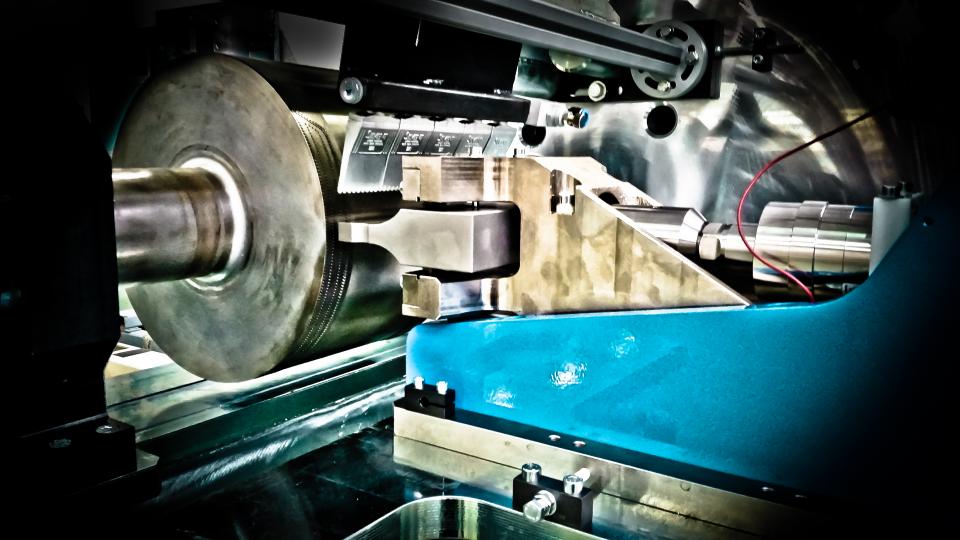

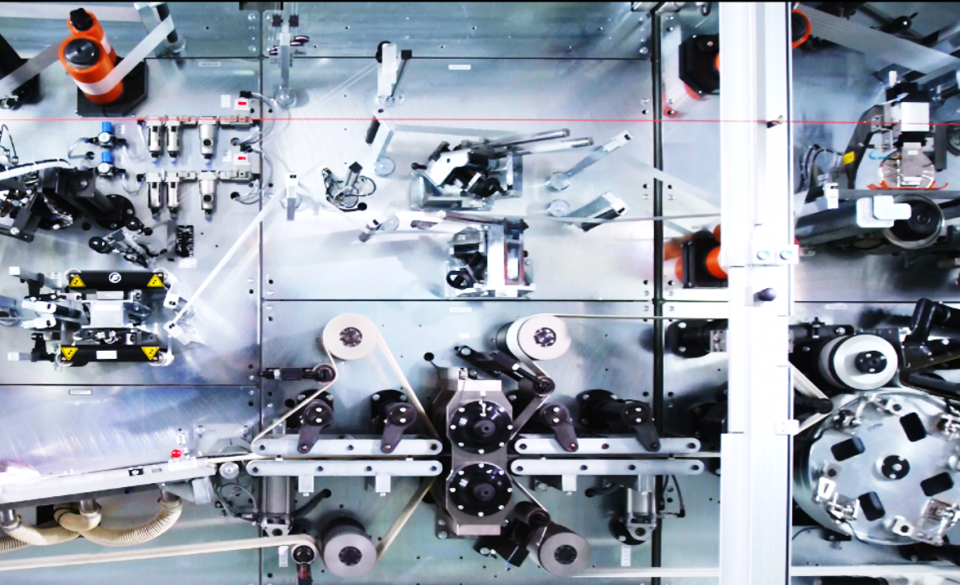

Zero Glue is a set of solutions for the material bonding with ultrasonic technology.

The most important benefits in eliminating the use of adhesives during the product assembly are the lower risk of glue contamination, the production costs reduction and the improvement of the quality and process performances.